We are delighted that our vessel, the Cable Innovator, has successfully completed a cable laying project for the Neptune Observatory project in the Cascadia Basin in collaboration with Ocean Networks Canada.

To learn more about this detailed project and how it sets the Observatory up for another successful year, click here.

Click here to learn more about our Subsea Cable Installation servicesFind

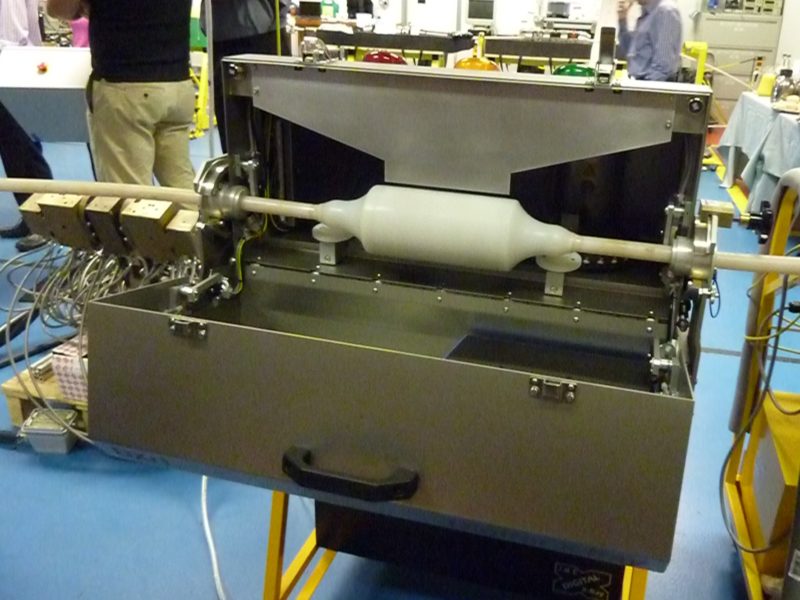

Global Marine’s Specialist Interconnectivity Solutions Team is very proud to have supported a state-of-the-art cable system designed to observe abyssal areas of the Ionian Sea. The “InSEA” cable system was successfully deployed to a depth of 2,300m, 30 Km off the Sicilian coast to monitor the Adriatic and Eurasian tectonic plates. The objective is to explore the utilization of seismometers and environmental monitoring sensors strategically placed within and around the repeater enclosures of conventional telecommunications cables, ensuring that the gathered data remains both scientifically and operationally uncompromised.

The system comprises of three repurposed submarine telecommunications repeater housings fitted internally with a variety of Güralp Systems Ltd specialist seismometers and data communication equipment and connected externally to both pressure and temperature sensors mounted on the cable 30 m from the main housing.

Using our specialist knowledge and experience Global Marine sustainably repurposed and retro fitted it’s bespoke composite optical/power penetrator technology into the 30-year-old Optical Amplifier Module (OAM) housings and bulkheads. Key to the success was the development and delivery of a unique external “on cable” sensor module pack solution by the Global Marine team. This provided a protective mounting and data cable interconnect to the temperature and pressure sensors remote from the main housing, negating the need to break into the underlying cable structure.

In the Global Marine Lab in Chelmsford, UK, modifications were made to original OAM terminations so that they could be interfaced with the related sensor packs using sustainably repurposed cable tails of a similar era to the housings. Once completed the units were transported to Catania for system integration on the cable vessel using Global Marine, Universal Jointing (UJ) technology prior to deployment.

The Interconnectivity team supported Güralp in the delivery of this SMART (Science Monitoring And Reliable Telecommunications) cable system, for their customer the National Institute of Geophysics and Vulcanology of Italy (INGV).

Using standard marine installation process and techniques, the system was successfully deployed and tested on 20th December 2023 and marks a significant industry milestone through the adoption of Global Marine ’s specialist integration solutions to realise the repurposing of submarine telecoms technology to advance subsea science. Global Marine is proud to have been involved in this unique and exciting project and would like to thank Güralp for entrusting us with the responsibility and showing confidence in our role in its successful execution.

Related Links:

InSEA SMART Cable: wet demonstrator project (guralp.com)

https://www.guralp.com/about-us/news-and-events/guralp-successfully-deploys-worlds-first-smart-cable

ITU/WMO/UNESCO IOC Joint Task Force

Seafloor fibre-optic cables become sensor stations – Science Issue 6688

One of the oldest and most well-known maritime superstitions was that bringing women aboard a vessel was bad luck. Fortunately all that has now changed, and we’re firm believers in supporting growing diversity across our workforce across the globe.

We spoke to one of our Chief Officers, Kaya Teare, about life offshore as a woman, playing a critical role onboard a submarine cable ship.

Kaya is one of our fantastic crew members, currently serving onboard the C.S. Sovereign in Portland, England. She has eight years of qualified experience on cable repair and maintenance vessels with Global Marine. She has previously served as a Third Officer, Second Officer, and Deputy Offshore Installation Manager (DOIM) and plans to obtain her master’s ticket in 2024.

After completing her honors degree in navigation and maritime science, Kaya Teare took to the seas to work on cable repair and installation vessels. Having moved up the ranks from Deck Cadet to Chief Office, she is a strong advocate for reducing the gender gap and including women in all teams and departments, especially at senior levels.

I have always lived by the sea and near ports. I was born in Osaka, Japan, a major port, and grew up in Peel, Isle of Man, a fishing town. I enjoyed kayaking, camping, and sailing as a teenager and was looking for my next adventure. When I was 18, I was ready to leave the island, travel, and live independently. I initially thought I would take a year out to travel and work as a stewardess on a superyacht. My friends and family asked me why I wanted to be a stewardess, and I quickly realised I didn’t.

I started researching jobs at sea / cadetships and decided I wanted to be a deck officer. I liked the sound of a course that would have a year in industry, learning how to navigate, being sponsored, and coming out with a professional qualification to start my career. When I was applying for sponsorship, I wanted to work on cable ships because they sail worldwide, have many personnel onboard, and don’t complete routine passages.

I don’t come from a family of mariners and didn’t know anyone working at sea before I started. I didn’t consider that I would be the only women in lectures / courses or onboard the vessels. I was always surprised and wondered why more women didn’t want to do this as a career. With hindsight, I don’t think women fear taking it up as a profession: I think they don’t consider it an option. I was lucky enough to have people around me that questioned me and helped me realize that there are more opportunities for women at sea

I grew up with two different cultures, as I am half Japanese and half Manx. I have always enjoyed working with people of different cultures and backgrounds. It is interesting to see how different cultures range in their working methods and how they approach situations. I see it as an opportunity to learn and see something from a different perspective. I never expect to be accepted and respect others people’s views. I think simply by being there and doing what I do, it will show people who have never seen women working at sea before that it is possible. I think this is the best way of showcasing what women at sea can do.

I have seen many positive changes in the industry, especially in the last three years. I now regularly sail with other women, whereas in the past, I was mostly the only woman onboard. Also in recent years, personnel with strong traditional opinions have retired and more personnel accepting of all genders are onboard cable ships.

I genuinely feel the company and my colleagues have given me equal opportunity and fully supported me. There are, of course, some characters who are not as accepting, but I have found over time they adjust to the change that they are not used to seeing. I believe over time being a woman at sea will not be a novelty. There is room for more women to work at sea, and they should feel we

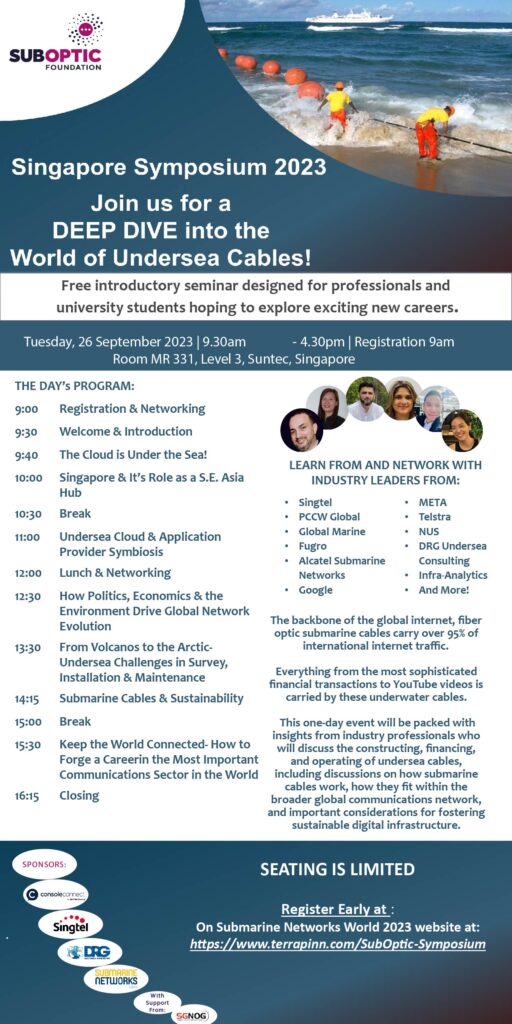

Our Head of Asia, Sheryl Ong, is going to be presenting at the SubOptic Foundation Symposium in Singapore in just a couple of weeks time.

It’s a great chance for professionals and undergraduates to get an exciting insight into the world of subsea cables and the potential careers available within the sector.

There’s still time to register to attend for free here: SubOptic Symposium (terrapinn.com)

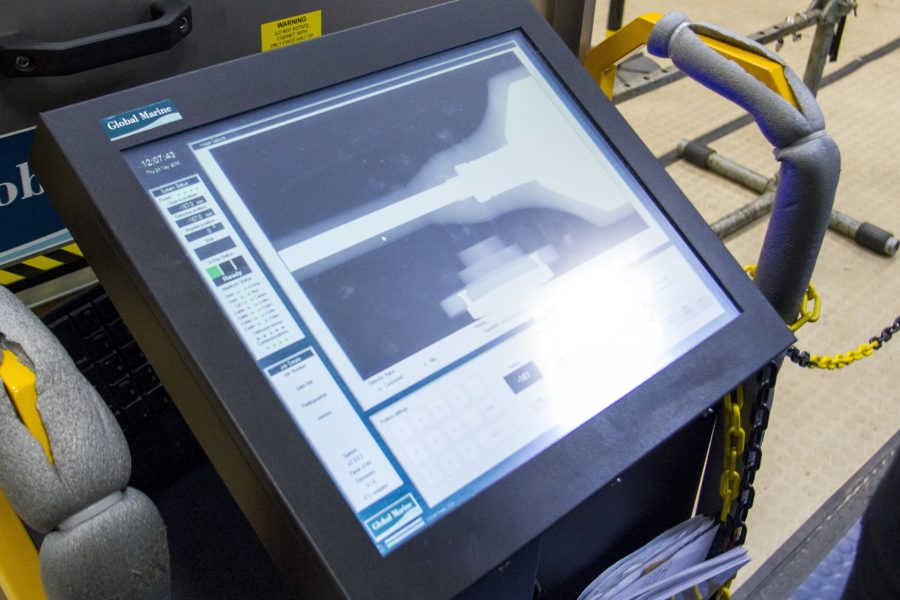

Chelmsford, 8 March 2023. Global Marine, a market leader in subsea fibre optic cable installation including cable data and route engineering as well as cable maintenance and Universal Joint technology, has marked the delivery of its 80th ‘DXr1’ digital X-Ray camera to the market.

When introduced a decade ago, the DXr1 camera, used to inspect the integrity of submarine cable joints following jointing and repair operations, eliminated the need for film technology. This had immediate environmental and operational cost saving benefits, with film plates and chemicals no longer being shipped across the world or disposed of and is just one of the small ways in which Global Marine is looking at more sustainable operations.

The digital radiograph images produced by the DXr1 are available instantly allowing assessment to commence right away, in more detail than before and from anywhere in the world, saving around 75% in time spent compared to the more traditional film methods. In an industry where project delays can cost tens of thousands of dollars per day as vessels remain on standby for extended periods, time savings like this are crucial. The evaluation record and original images, retained electronically, negate the need for archiving and preservation of film plates.

Bruce Neilson-Watts, CEO of Global Marine Group said, “We’re proud that our digital X-Ray camera continues to be at the forefront of technology supporting the maintenance of the world’s critical telecommunications infrastructure. In the 10 years since we developed the camera, we have supplied 80 of these to customers around the world. And there’s no greater endorsement than our customers, the key players in the telecom industry, continuing to return time and again to supply multiple vessels in their fleet with our technology.”

The 80th unit was delivered to a cable installation vessel currently installing a trans-Pacific system, and has already completed joint X-Rays on its first project. Global Marine have an additional five DXr1 cameras on order, for delivery to customers early in 2023.

Global Marine has completed the initial subsea fibre-optic cable route survey scope for the Scottish Government’s Reaching 100% Programme (R100), being delivered by Openreach on behalf of BT. The project covers inter-island connections between Orkney, Shetland, and the Inner Hebrides as well as two connections back to the Scottish mainland.

The Scottish Government-funded R100 project aspires to extend superfast broadband capabilities at speeds of at least 30Mbps to every premises in Scotland.

Utilising the extensive subsea knowledge of our sister company OceanIQ, also part of the Global Marine Group, and specialist service provider Fugro, the cable route surveys are now complete, ahead of the 16-route cable lay. The fibre optic cable installation is scheduled to commence early in 2022 and will be delivered by Global Marine’s multi-purpose vessel, Normand Clipper.

Three survey vessels were mobilised on the project to complete specific scopes of geophysical and geotechnical survey work along the different cable routes. The scope of work also included an Unexploded Ordinance (UXO) assessment. As well as land survey activities, an aerial lidar survey was conducted to acquire topographical and inter-tidal survey data and photogrammetry.

Bruce Neilson-Watts, Managing Director of Global Marine said: “We are pleased that this initial stage of the project is almost complete. The diverse elements of the subsea survey data will combine together to give a rich and detailed picture of the seabed environment and shallow soils regime, providing essential information to deliver this high-profile project safely and effectively for the long-term benefit of many of Scotland’s residents.”

Mr Neilson-Watts continued: “With 16 routes throughout the Northern and Western Isles of Scotland, there has been great cooperation between our survey teams and local fisheries, and other users of the sea to ensure safe and efficient working, with minimal disruption to all stakeholders.”

Clive Downing, R100 Programme Director, Scottish Government said: “We recently announced the start of build for Scottish Government’s R100 North contract area, where 16 new subsea cables will be laid to provide superfast broadband access to some of the hardest-to-reach areas.

“As a result of the R100 North contract many homes and business will benefit from full fibre broadband, far exceeding our superfast commitment and providing future-proofed full fibre connectivity to some of the most rural and remote communities in Scotland. This is something that will make a huge difference to both residents and businesses as we continue to work, learn and access public services remotely.”

“Fugro and Global Marine have successfully mapped out the subsea routes through complex underwater and overhead surveys and this work is the first step in connecting islanders to faster broadband. I look forward to hearing about subsea progress in the upcoming months.”

Robert Thorburn, Openreach partnership director for Scotland, added: “R100 is a hugely important project and the subsea build is both complex and sensitive. Over this summer, our specialist partners, led by Global Marine, have used innovation and technology – in the air and on land and sea – to gather the extensive, in-depth knowledge we need to design the full fibre network to more islands.”

Five-year extension runs to end of 2022

Chelmsford, [Wednesday 3rd January 2018] Global Marine, a market leader in subsea fibre optic cable installation and maintenance solutions to the telecoms and oil & gas sectors and part of the Global Marine Group (GMG), announced today that its maintenance contract with SEAIOCMA (South East Asia and Indian Ocean Cable Maintenance Agreement) has been extended for five-years, running to the end of 2022.

The SEAIOCMA maintenance zone agreement, which is a co-operative club managed by 46 cable owners, provides the repair of submarine cables that carry international telecommunications traffic. SEAIOCMA spans the area between Djibouti in the west, Perth in the south, Guam in the east and the northern tip of Taiwan. This is the third and final of Global Marine’s three long-term maintenance contracts renewed since the beginning of 2016 (NAZ (North America Zone) announced March 2016 and ACMA (Atlantic Cable Maintenance Agreement) announced January 2017).

Under the terms of the extended contract, which came into effect on 1 January 2018, and expires on 31 December 2022, Global Marine will provide a newly constructed depot in Subic Bay, Philippines. The new depot will continue to serve as the base of Global Marine’s vessel the Cable Retriever, a purpose-designed cable ship equipped with a 600 horsepower ROV (remote operated vehicle), capable of burying cable up to three metres below the sea bed and mobilising within 24 hours of a call-out. The Cable Retriever is operated by experienced and fully trained personnel and features specialist equipment.

Global Marine has been providing maintenance services continuously to SEAIOCMA since its inception in 1986 and has completed more than 600 repairs. During that time the network has expanded from 34,000 km of cable maintained to encompass more than 111,000 km. The extension of the SEAIOCMA agreement demonstrates continued customer recognition of Global Marine’s reliability in support of long-term contracts, and its ability to deliver leading subsea maintenance to customers around the world.

“There is no greater endorsement of your success than a contract extension from an existing customer,” said Bruce Neilson-Watts, Managing Director of Global Marine. “SEAIOCMA has again placed confidence in our capabilities, primarily because we provide certainty and minimise disruption. Over our long and successful history, Global Marine has proved time and time again that we are both resilient and flexible enough to provide new solutions that aid future market development.”

Global Marine currently delivers support in three of the world’s six cable maintenance zone agreements. Combined with its joint venture, SBSS, Global Marine maintains 33 percent of fibre optic cable lying across the world’s ocean floor. In the past five years the Company has achieved 99.7 percent of the contractual KPIs across all of its maintenance agreements.

Global Marine Group (GMG) has launched a new Safety, Security and Environmental Management System (SSEMS).

The system has been organised, planned and implemented by GMG to ensure the safety and operational excellence of its people and assets, as well as to safeguard the environment. Structured to meet the requirements of the Offshore Vessel Management and Self-Assessment (OVMSA) programme. Along with the stipulations set out in the International Safety Management (ISM) Code, the new SSEMS enhances the Company’s regulatory compliance and supports the continual evolution of industry standards.

Safety is the number one priority at GMG, Global Marine and CWind, and we are proud to have completed 1.65 million working hours in 2016 without a single injury, a remarkable achievement given the potentially hazardous environments in which our people and assets operate.

As well as OVMSA and the ISM Code, the new SSEMS supports GMG’s status as an active member of the International Marine Contractors Association (IMCA); staff from the Company’s RQHSE (Risk Quality Health Safety & Environment) team sit on IMCA’s HSSE (Health, Safety, Security & Environment) committee. GMG is also proud to hold the Order of Distinction, an honour bestowed by RoSPA (Royal Society for the Prevention of Accidents) on organisations achieving a minimum of 15 consecutive Gold Awards (GMG has 18). Gold Awards are presented in recognition of outstanding occupational health and safety standards.

CS Recorder will Support Telecoms Customers with Installation Projects Across the Globe

Global Marine Systems Limited, the world leader in subsea cable systems design, installation and maintenance, announced today the addition of the 6,200 ton cable deadweight CS Recorder to its existing fleet of vessels. Built in 2000, the vessel formerly known as the Maersk Recorder, has previously been chartered by Global Marine for numerous cable installation projects and has since successfully completed work in the oil and gas and renewables sectors. The newly named CS Recorder is intended to support the telecoms installation business growth over the next 5-10 years, with a number of critical projects scheduled during 2018, 2019 and 2020.

CS Recorder will be equipped with a plough system and Remotely Operated Trenching Vehicle (ROV) to ensure it is fully prepared to undertake the full range of telecoms cable installation projects.

“The addition of this latest vessel to our fleet demonstrates our continuing commitment to ensuring the appropriate assets are available to meet our customers’ needs across the globe, and to our core business of telecoms cable installation, even in a market where the current trend is for assets to be relinquished, rather than added,” said Bruce Neilson-Watts, Managing Director, Telecoms at Global Marine.

The CS Recorder joins Global Marine’s current fleet of 25 vessels, which now consists of four maintenance vessels, (Cable Retriever, Pacific Guardian, Wave Sentinel, Cable Innovator); three installation vessels, (CS Recorder, C.S. Sovereign, Networker); and 18 CWind Crew Transfer Vessels. She replaces the Cable Innovator following her reassignment in the fourth quarter of 2016 to become a dedicated maintenance vessel for the North America Maintenance Zone (NAZ) submarine cable contract; a contract running through to the end of 2024. The CS Recorder is expected to be available for use in the fleet for installation projects at the end of the first quarter 2017.

Global Marine Systems Limited, the world leader in subsea cable system design, installation and maintenance, announced today that it has been awarded the renewal of the Atlantic Cable Maintenance Agreement (ACMA), alongside its Atlantic partner for maintenance services, Orange Marine. The new contract began on January 1, 2017, and runs for five years, through to December 2021.

ACMA is a non-profit cooperative subsea maintenance agreement consisting of 60+ members. ACMA members are companies responsible for the operations and maintenance of undersea communications and power cables, as well as Oil & Gas Platform operators, in the Atlantic, North Sea and South Eastern Pacific Ocean. Global Marine has delivered maintenance services across the Atlantic since the first cable was laid in the 19th century and has been a key supporter of ACMA since its inception in 1965. Global Marine currently delivers maintenance support in three of the six zone agreements globally.

Global Marine’s dedicated maintenance vessels, the Wave Sentinel and Pacific Guardian, will be servicing ACMA17 from their respective bases in Portland, UK and Curacao in the Netherlands Antilles. Both vessels are fitted with powerful remotely operated vehicles, the Atlas and ST200 series respectively, which offer flexible, effective solutions for monitoring, cutting and burying cable.

Global Marine has played a pioneering role in the development of undersea cable repair and maintenance solutions for well over a century, having performed approximately 33 percent of all maintenance operations on fibre optic cables globally. The Company is a founding and current member of the Universal Joint Consortium, an international cross-industry body supporting the manufacturers and consumers of Universal Joint and Universal Coupling technology. Global Marine remains at the forefront of this vital part of the industry through its well-renowned training school utilised by many of the key telecoms installation and maintenance companies and cable manufacturers around the world.

“We appreciate the confidence placed in us by the Atlantic Cable Maintenance Agreement members and look forward to ensuring that their cables are effectively protected,” said John Walters, Maintenance Director, Global Marine. “The resilience of communication networks throughout the Atlantic and Western South America is critically important to companies and consumers alike, and Global Marine is proud to again be of service to maintain these vital connections.”

Mr. Walters continued, “The contract award is again a vote of confidence in the zone model, where quality of service and vessel availability are the priority of customers and the service provider, and where members are able to participate in the development of the service offering for the future.”

“We trust the Global Marine and Orange Marine solution,” said Alasdair Wilkie, Chairman, ACMA. “Over decades, the two companies have repeatedly demonstrated their pedigree and experience in this highly specialised area.”